Spur / Helical Gears

From 0.3 module to 24 module in accuracy class ‘C’ to ‘AA’ with finishing, pregrinding or roughing profiles with various profile design modifications such as semi topping, protuberance, tip relief.

Key Splines

For generating parallel or angular splines; straight or helical splines offered with profile modifications like semi topping, undercutting, shoulder clearance, etc. Finishing or pregrinding hobs are offered with precision unground or ground profile depending on component accuracy requirements

Chain Sprocket & Timer Pulleys

For sprockets as per ANSI, BS, IS or any other standards or with non-standard forms. For timer pulleys as per BS/HTD or any other standards or non-standard profiles. These hobs are offered with ground or unground profiles and topping or non-topping designs.

Worm Gears

To achieve desired contact patterns – prime requirement on hobbed worm gears, Jainex Aamcol have developed their expertise through long extensive mathematical modelling, data simulation and practical applications. Hobs can be hollow type or integral shank type depending upon strength constraints. Tangential, radial, topping or non-topping hobs and special reaming type finishing hobs are also offered.

Ratchet Wheels

Fixed position hob for generating teeth on ratchet wheel. This hob unlike a conventional hob can cut without forming a fillet

Special Hobs for Blocked Teeth

Special multistart hobs for components having block teeth like indexing splines.

Roughing-finishing Multi Thread Hobs

The solution for efficient and economical hobbing of large size gears of coarse pitch (5 module & above) requiring subsequent teeth finishing operation. The special chip breakers provided on roughing starts allow heavy feed rates to be applied without overloading hob and hobbing machine. This reduces peak jerk loading on machine and ensures accurate part quality.

Roughing Finishing Two Section Hobs

Jainex Aamcol has developed special combination hobs having roughing and finishing sections on one piece monoblock and split two piece construction. Roughing section is provided with special chip breakers allowing more efficient cutting even at higher cutting speeds /feeds

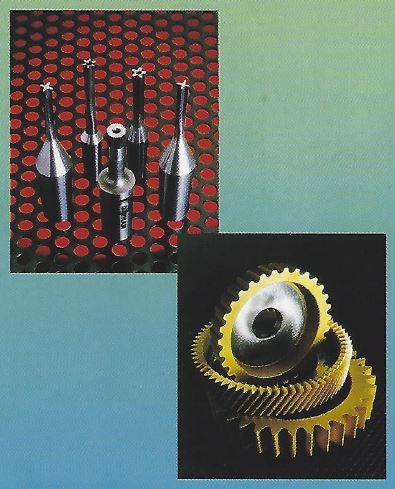

Miling Cutters

Offers precision form relieved ground or unground profile cutters ranging from standard single angle, double andgle, convex/conclave cutters to most complex intricate profile cutters like end mill type gear cutters, spline milling cutters, turbine blade profile milling cutters, etc.

These milling cutters are made out of high alloy super high speed steel; with precision ground or unground forms; with straight or helical flutes for shear cutting; continuous or intermittent (staggered) cutting teeth; with or without chip breakers; radial, positive or negative rake tooth faces; with radial, axial or undercutting clearances; individual, gang or solid sections. As cutter teeth are cam relieved, only rake faces need to be sharpened with changing the tooth form through their full life. Cutter accuracy is maintained as long as they are accurately resharpened. This simplifies tool maintenance and provides more consistent quality. These cutters provide high degree of accuracy and efficient cutting geometry and hence ordinary cutters can be comparable in no way with these Jainex Aamcol special cutters. Some important applications of these cutters are highlighted below:

- Spur gear teeth milling for specific number of teeth or in sets of 8 and 15 cutters of IS or BS standards.

- Sprocket teeth milling cutters, precision ground or unground profile

- Rack teeth milling of highest accuracy, single or multistrand, precision ground or unground profiles

- Worm thread milling, roughing or finishing, ground or unground form

- Spline milling on universal or HURTH type machines

- Special serration milling on m/c chuck-jaws, automobile con-rod jaws, etc.

- Special narrow & deep groove milling on automobile con-rods

Shank Type Gear Shaper Cutters

These are primarily designed for cutting internal gears, splines and serrations, both spur and helical. May also be designed for externals if required.

These cutters are full form generated however small the pitch circle diameter (PCD) although strength of the cutter produced is the limiting factor.

The strength and rigidity of shank type cutters is greatly improved by the DATHAN ribbing method and is especially advised for those of small PCD

Disc Type Gear Shaper Cutters

Dathan disc type cutters can be designed and produced for cutting any type of gear, internal or external, spur or helical.

They can also be designed to cut splines, serrations, sprockets or other involute forms. The cutters are full form generated using the Dathan 'pass thro' method.

These cutters may be manufactured with bore diameters from 10mm to 120mm or 0.5" up to 4", cutter diameters (pitch circle diameter) from .75"(19mm) to 13.75"(350mm) and can be manufactured to any world standard or to any specified requirement.